Digitalisation and Integration: sustainable efficiency

Panel building & switchgear manufacturing companies are driving the digital transformation in a number of areas with some production and organisational processes having already been digitised. However, the complexity and many production systems is preventing the rapid transition in some cases. Individual items of machinery and equipment have different lifecycles, which means processes are already automated, while others are still completed manually.

Despite these challenges, digitalisation offers a whole host of opportunities, with Industry 4.0 paving the way for smart factories and predictive maintenance. Panel building and switchgear manufacturing cycles are now incredibly tight. Huge time and cost pressure is the norm, with increasingly complex systems having to be produced in ever shorter timeframes and at lower costs. The quality of products and services used to be the key success factor, but having the most efficient process is now just as important as a high-quality product in gaining a vital edge over the competition.

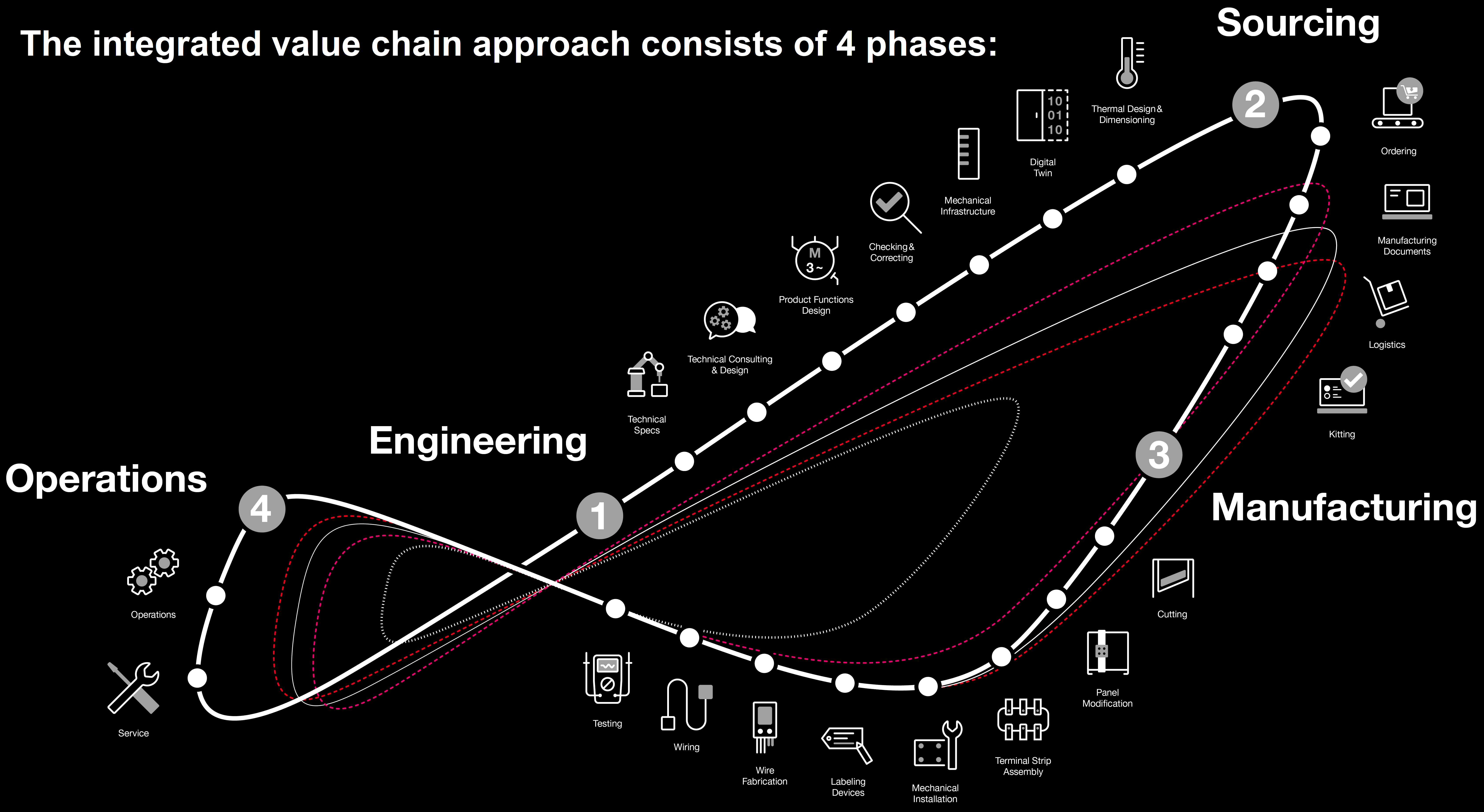

An integrated value chain

Manufacturers that focus on the entire value chain – from planning and designing a product through to the placing of orders, production, delivery and service operations – will increase their throughput, boost their efficiency and achieve crucial competitive advantages.

Discover how by combining engineering solutions from EPLAN with system and automation expertise from Rittal, optimises and industrialises your panel building and switchgear manufacturing processes by downloading the latest whitepaper:

Comments